Plastic injection molding machine: what it is, how it works and how to choose the right model for your industry

Choosing a plastic injection molding machine is not just a purchasing decision, but a strategic decision that directly impacts the…

Choosing a plastic injection molding machine is not just a purchasing decision, but a strategic decision that directly impacts the efficiency of the production cycle, the cost per piece and the standardization of final quality.

For industrial managers, understanding the technical, operational and economic aspects of this equipment is essential to making informed decisions, especially in the face of growing demands for speed, automation and energy efficiency.

In this article, you will gain an in-depth understanding of how a plastic injection molding machine works, its industrial applications, the differences between the main types of machine and the technical criteria that should guide your choice.

At the end, we’ll show you how Alltech structures complete, connected solutions to transform industrial performance with cutting-edge technology.

What is a plastic injection molding machine and how does it work in the industrial process?

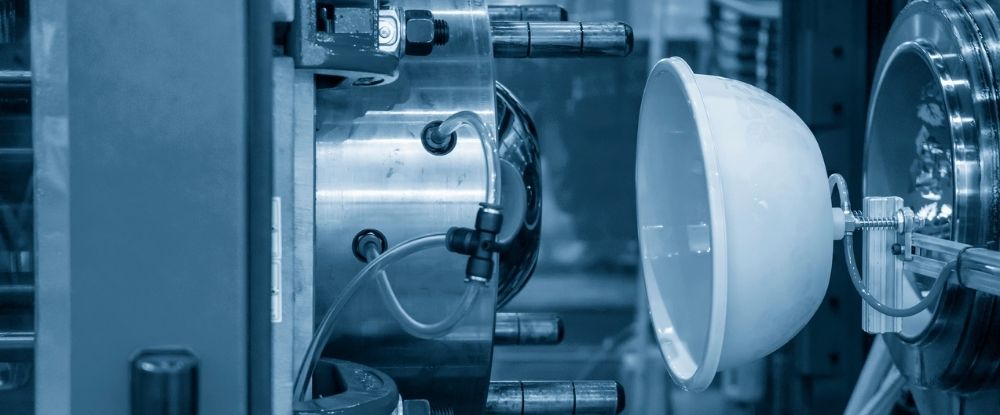

A plastic injection molding machine is a machine designed to transform thermoplastic polymers through the injection process. In this method, the plastic resin (in pellet form) is fed into the machine, melted in a heated chamber and then injected under pressure into a metal mold – which will give the final shape to the part.

This injection cycle involves three main stages:

- Dosing and plasticizing: the material enters the plasticizing screw, which rotates under high temperature and transforms the polymer into a pasty state;

- Injection: the molten material is injected into the mold by hydraulic or electrical action, filling all the details of the cavity;

- Cooling and extraction: the mold is cooled in a controlled manner and the solidified part is ejected to start a new cycle.

This process is highly controlled by automation systems and sensors, which allows for dimensional standardization, repeatability and geometric precision, which are fundamental in sectors where technical tolerances are required.

What are the technical benefits of a plastic injection molding machine in industry?

The plastic injection molding machine’s main advantage over other polymer forming processes lies in its production efficiency combined with dimensional quality. See below for the main technical benefits:

- High productivity with low cost per piece: in cycles lasting between 10 and 60 seconds, it is possible to produce thousands of pieces a day with minimal human intervention;

- Geometric versatility: allows parts to be molded with complex variations in thickness, internal channels, locks, fittings and fillets;

- Precise thermal and mechanical control: guarantees stability in the polymer flow, avoiding burrs, bubbles or deformations;

- Material savings: with the use of optimized channels, it is possible to minimize losses and facilitate the reuse of recycled burrs (reprocessing);

- Automation compatible with Industry 4.0: on-board sensors, real-time control of pressure, temperature, closing force and cycle time.

Which industrial sectors use plastic injection molding machines intensively?

Injection molding machines are present in practically every sector that depends on structural, functional or finishing plastic components. Some of the main segments are:

Automotive

Injection molding machines are used to manufacture air conditioning ducts, interior panels, consoles, brackets, connectors and moldings. Dimensional stability is essential for the assembly and safety of systems.

White goods industry

Produces washing machine casings, internal components for microwaves, fans and functional parts with thermal resistance.

Electronics

Manufacture of housings, keys, internal parts for notebooks, connectors and fastening systems, requiring precision and insulation.

Medical-hospital sector

Use of sterilizable resins for syringes, valves, ampoules, tubes and medical safety devices.

Furniture and agricultural sector

Seats, backrests, supports and structural parts, using fiber-reinforced composites.

What types of plastic injection molding machines are there? Comparative technical analysis

In the plastics processing industry, choosing the right type of injection molding machine is a critical decision that directly influences productivity, the dimensional stability of the parts and the energy cost of the operation. Each type of injection molding machine offers specific performance, strength, precision and consumption characteristics, which makes it essential to understand how they work and in which contexts they are best suited.

Below is an in-depth comparison of the three main types of injection molding machine: hydraulic, electric and hybrid.

1. hydraulic injection molding machine: strength and robustness for large applications

Hydraulic injection molding machines use hydraulic fluid-based pressure systems to drive the screw and the mold closing mechanism. They are known for their high clamping force, which makes them ideal for molds with multiple cavities or large volume parts.

- Clamping capacity of over 500 tons, for robust and technical parts;

- They are particularly suitable for the automotive, white goods and housewares industries;

- Their system, although efficient, requires greater energy consumption and more frequent maintenance due to wear and tear on the hydraulic pumps, hoses and valves;

- Ideal for operations that prioritize strength and an affordable initial cost, even with higher consumption over the long term.

2. Electric injection molding machine: precision, speed and energy efficiency

Electric injection molding machines replace the hydraulic system with high-performance electric motors (servomotors), which precisely control each stage of the cycle: dosing, injection, repression and extraction.

- They guarantee strict dimensional repeatability, ideal for parts with tight tolerances and aesthetic requirements;

- They reduce energy consumption by up to 70% compared to hydraulic machines, thanks to the on-demand operation of servomotors;

- They are quiet, clean (no risk of oil leaks) and require little mechanical maintenance;

- They are widely used in the production of items for the medical-hospital sector, electronics and technical packaging;

- Their limitation is their closing force, which is generally lower than hydraulic models.

3. Hybrid injection molding machine: balance between power and control

Hybrid injection moldingmachines combine the best of both worlds: they use electric servomotors for stages such as dosing and injection (where precision is critical), and hydraulic systems for closing the mold (where brute force is required).

- They offer versatility for different types of production, with capacity for small and medium-sized parts while maintaining good energy performance;

- They are ideal for operations that require fast cycles, thermal stability and high strength, such as in the technical auto parts industry or structural plastic parts;

- They have an intermediate cost, but provide excellent value for money for companies looking to increase performance without sacrificing strength and precision;

- They facilitate the transition from traditional factories to more digitalized and efficient models.

Plastic injection compared to other processes

Compared to other plastic forming methods such as extrusion, blow molding or thermoforming, injectionmolding stands out in the following respects:

- Extrusion: ideal for continuous profiles (such as tubes and wires), but does not allow complex geometry like injection;

- Blow molding: used for hollow bottles and jars, it has less control over thickness;

- Thermoforming: great for trays and flat parts, but with poor detail accuracy.

The plastic injection molding machine surpasses these processes when the requirement involves:

- Dimensional repeatability;

- Complex three-dimensional geometry;

- High productivity with low waste;

- Integration with automation and feedback systems.

How do you choose the right plastic injection molding machine for your operation?

Choosing the right machine requires more than analyzing injection capacity. You need to understand the process as a whole, taking into account:

- Size and complexity of the part (volume injected, number of cavities);

- Processed material (PP, ABS, PA, PC, with or without fillers);

- Desired production cycle (time and daily volume);

- Energy availability and technical infrastructure;

- Need for integration with peripherals and digital systems.

It is also worth noting that more modern models already incorporate digital control, pressure and temperature sensors, real-time feedback and integration with ERPs, bringing the injection molding machine into line with the principles of Industry 4.0.

A common mistake is to choose a machine with more power or capacity than necessary, resulting in disproportionate energy consumption and low efficiency. That’s why technical advice is essential to determine the exact configuration of the ideal injection cell.

Alltech: technology, automation and intelligence applied to the injection process

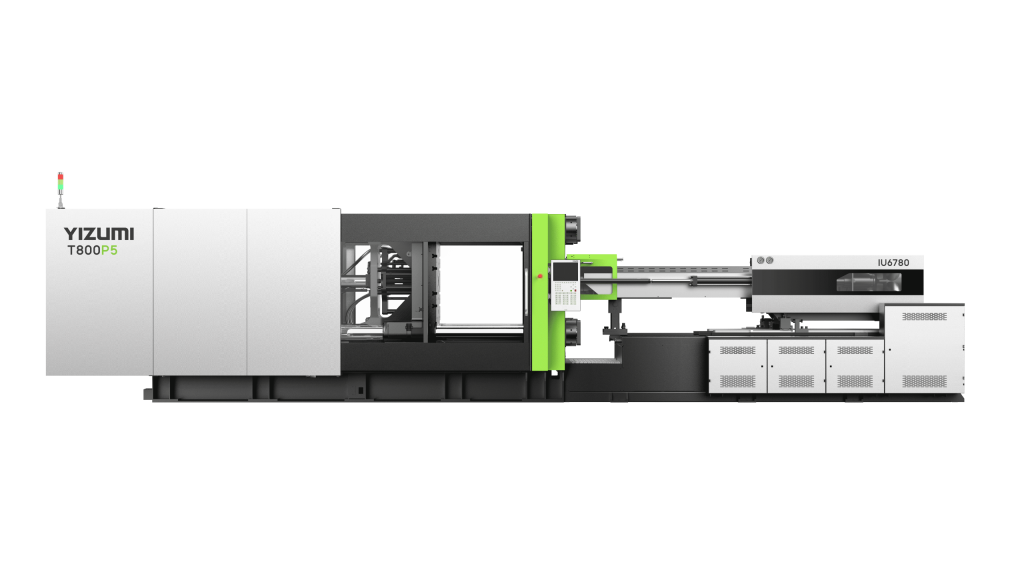

Alltech offers complete solutions for industries looking not just to mold parts, but to transform their operations with technology, performance and data intelligence. Our portfolio includes:

- Hydraulic, electric and hybrid injection molding machines with customizable engineering;

- Integration with peripherals such as dosers, chillers, conveyors and Cartesian robots;

- Real-time supervision systems to monitor efficiency, consumption, faults and performance;

- National technical support, productivity consultancy and remote service.

In addition, we connect the entire production journey with partners such as Bortopack, which complements the process with automatic packaging machines. In this way, injected items, such as PVC fittings, jars or cups, are already packaged and ready for the market. This continuous flow reduces operating costs, eliminates rework and speeds up time-to-market.

Discover the Alltech Ecosystem, a structure designed to provide complete support for your industry – from production to maintenance, from machine to data.